Science for a sustainable economy

Ostrom Polymers is dedicated to reducing the environmental burden of plastics.

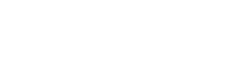

Ostrom 97 – Made with 97% post-consumer recycled material this composite is suitable for extrusion, injection molding, or compression molding.

Properties | |||

Melt Index: | · 22 (g/10 min@285°C/2.16 Kg) | ASTM D1238 | |

Vicat softening temperature | · 92°C | ASTM D1525 | |

Melting Point | · 123/250°C | ASTM D3418 | |

Crystallization Point | · 109/209°C | ASTM D3418 | |

Flexural Modulus | · 410 MPa | ASTM D790 | |

Tensile Strength @ Break | · 10.3 MPa | ASTM D638 | |

Tensile Strength @ Yield | · 10.6 MPa | ASTM D638 | |

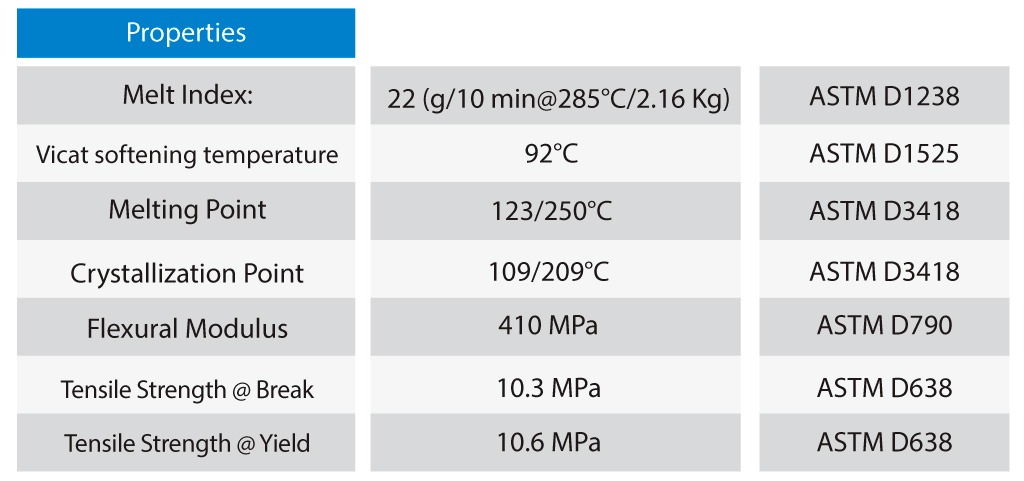

Ostrom 95 – Made with 95% post-consumer recycled material this composite is suitable for extrusion, injection molding, or compression molding.

Properties |

|

| |

Melt Index: | · 28 (g/10 min@285°C/2.16 Kg) | ASTM D1238 | |

Vicat softening temperature | · 180°C | ASTM D1525 | |

Melting Point | · 122/252°C | ASTM D3418 | |

Crystallization Point | · 107/209°C | ASTM D3418 | |

Flexural Modulus | · 1005 MPa | ASTM D790 | |

Tensile Strength @ Break | · 13.9 MPa | ASTM D638 | |

Tensile Strength @ Yield | · 14.0 MPa | ASTM D638 | |

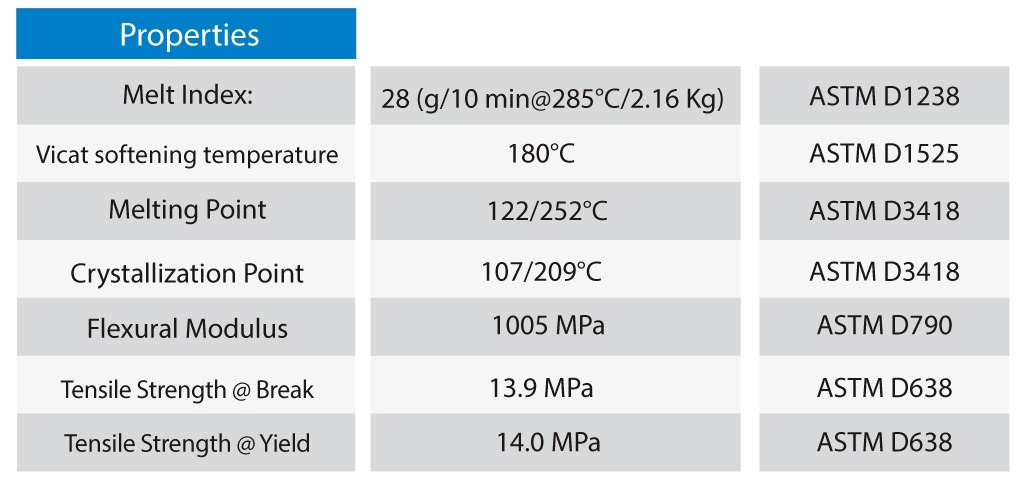

Ostrom 80 – Made with 80% post-consumer recycled material this composite is suitable for extrusion, injection molding, or compression molding.

Properties |

|

| |

Melt Index: | · 14 (g/10 min@285°C/2.16 Kg) | ASTM D1238 | |

Vicat softening temperature | · 178°C | ASTM D1525 | |

Melting Point | · 123/247°C | ASTM D3418 | |

Crystallization Point | · 107/209°C | ASTM D3418 | |

Flexural Modulus | · 965 MPa | ASTM D790 | |

Tensile Strength @ Break | · 25.7 MPa | ASTM D638 | |

Tensile Strength @ Yield | · 1.0 MPa | ASTM D638 | |

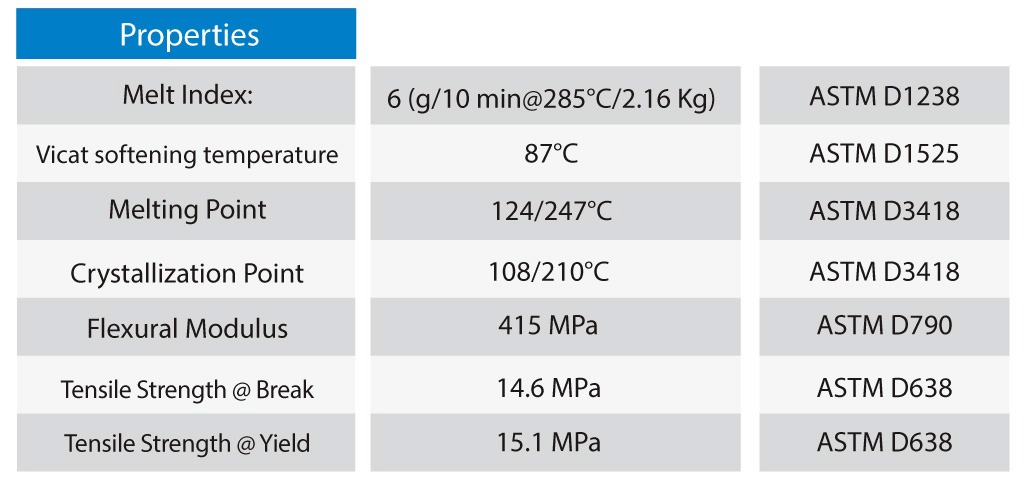

Ostrom 504 – Made with 80% post-consumer recycled material this composite is suitable for extrusion, injection molding, or compression molding.

Properties |

|

| |

Melt Index: | · 6 (g/10 min@285°C/2.16 Kg) | ASTM D1238 | |

Vicat softening temperature | · 87°C | ASTM D1525 | |

Melting Point | · 124/247°C | ASTM D3418 | |

Crystallization Point | · 108/210°C | ASTM D3418 | |

Flexural Modulus | · 415 MPa | ASTM D790 | |

Tensile Strength @ Break | · 14.6 MPa | ASTM D638 | |

Tensile Strength @ Yield | · 15.1 MPa | ASTM D638 | |